Wall Shelf Pro

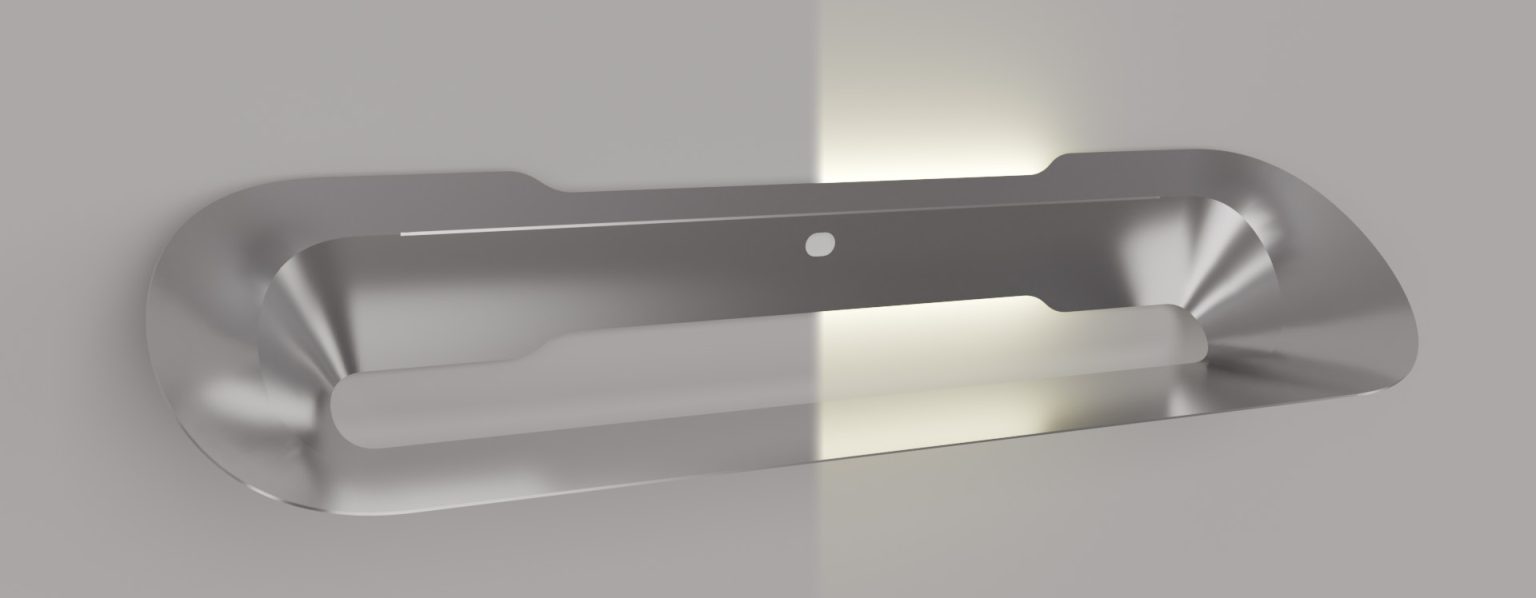

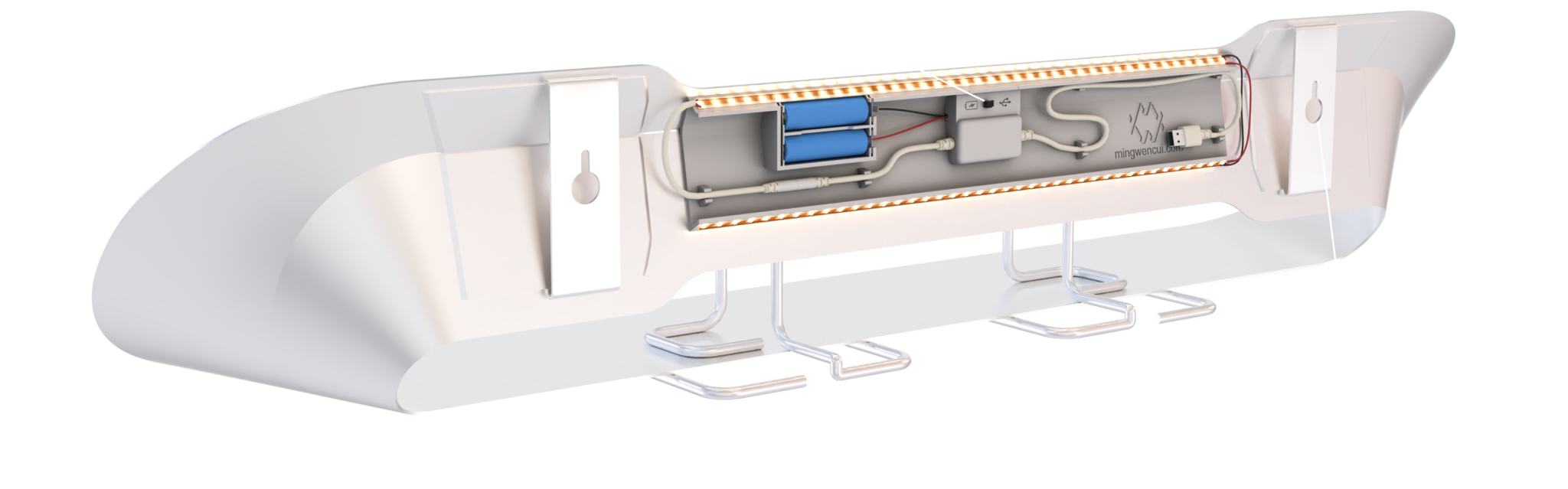

The Pro version features integrated lighting, which the standard model lacks. This advanced lighting enhances visibility and usability, making it perfect for low-light environments and adding a touch of modern elegance to any setting.

Why it is PRO?

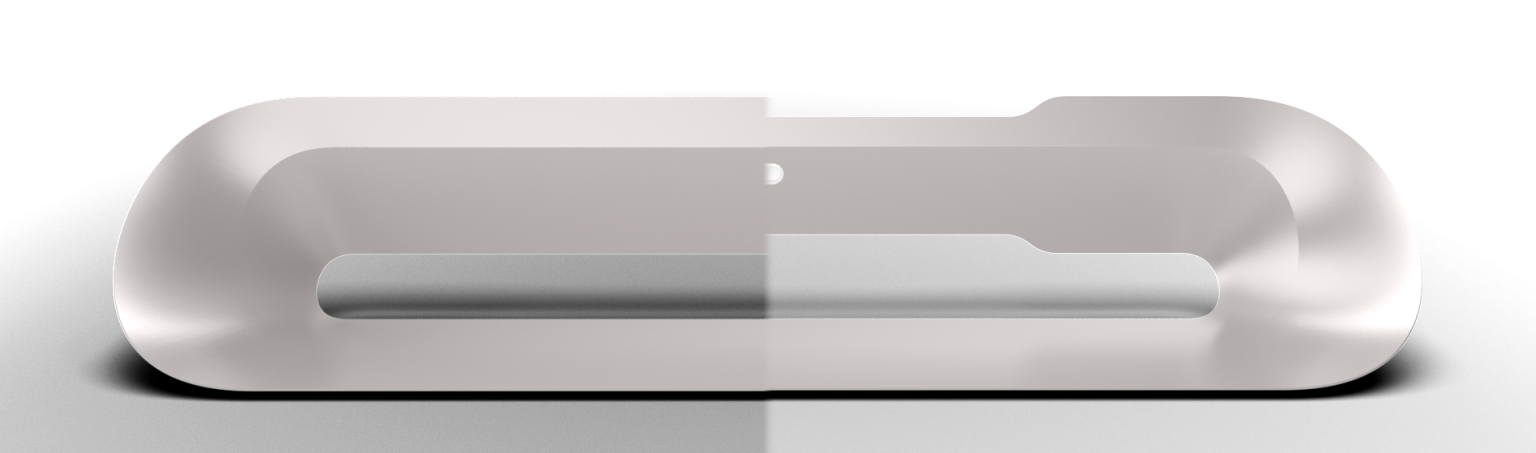

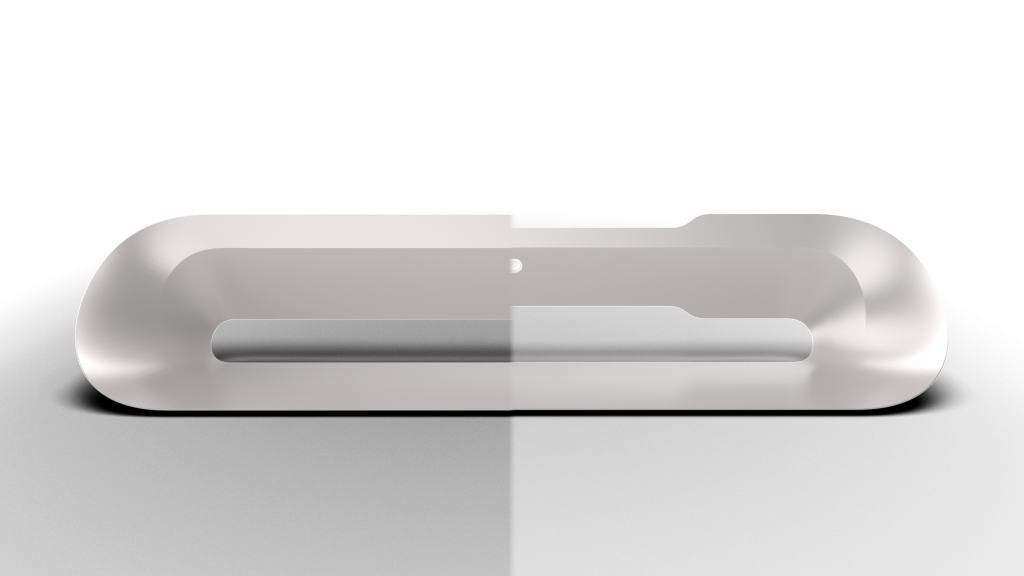

Standard version (left) VS Pro (right)

Light off (left) VS Light up (right)

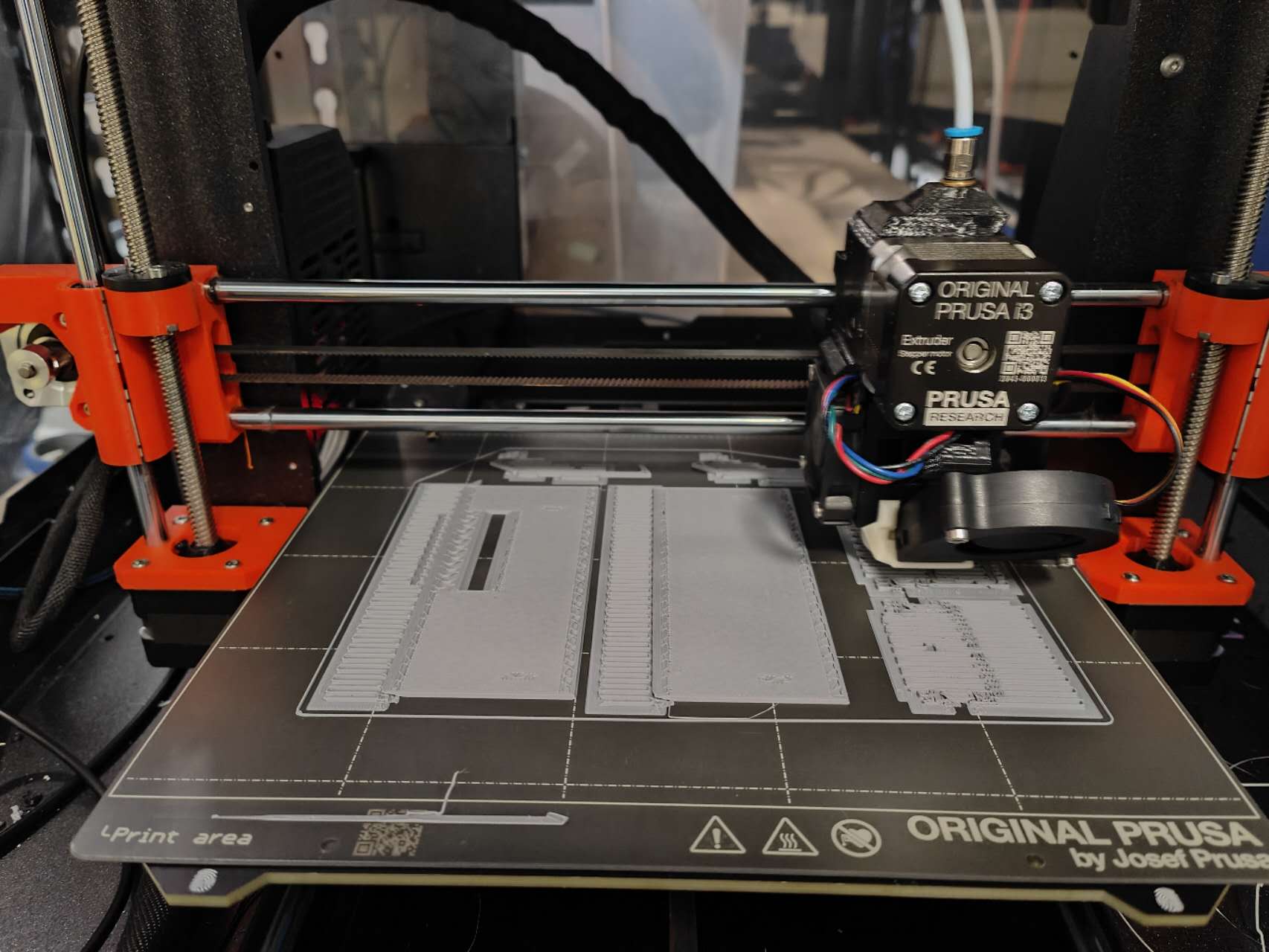

Work process

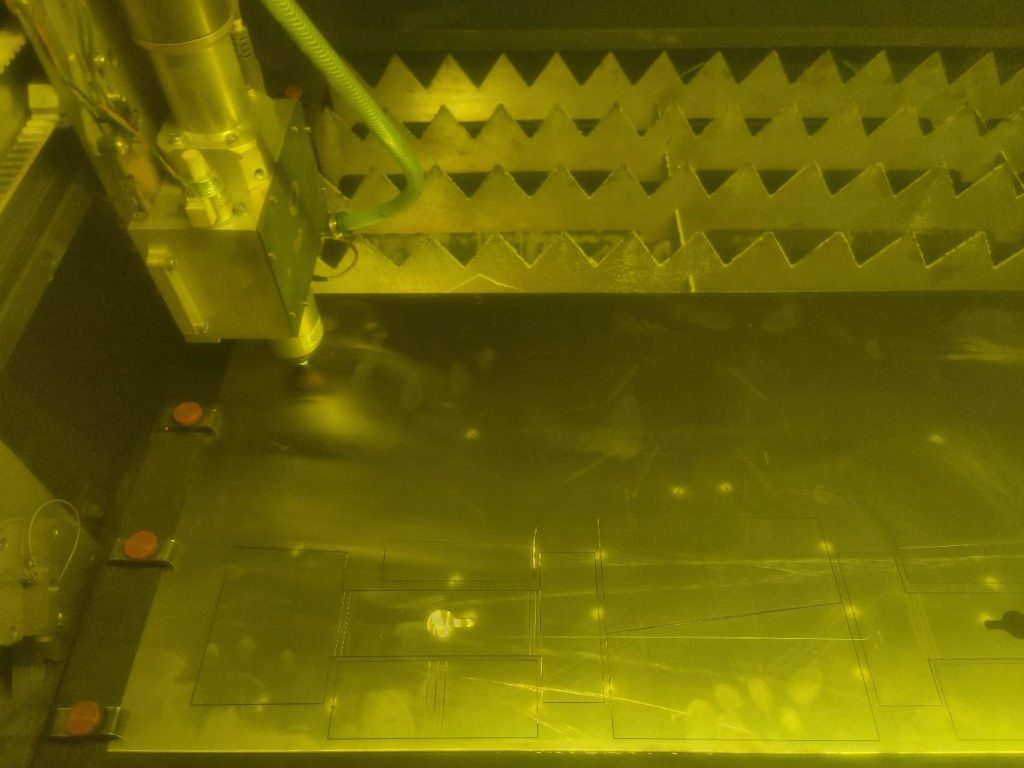

Fiber laser cutting:

Two sheets: 12 * 24″ (16 Ga.) 304 #4 Brushed Finish.

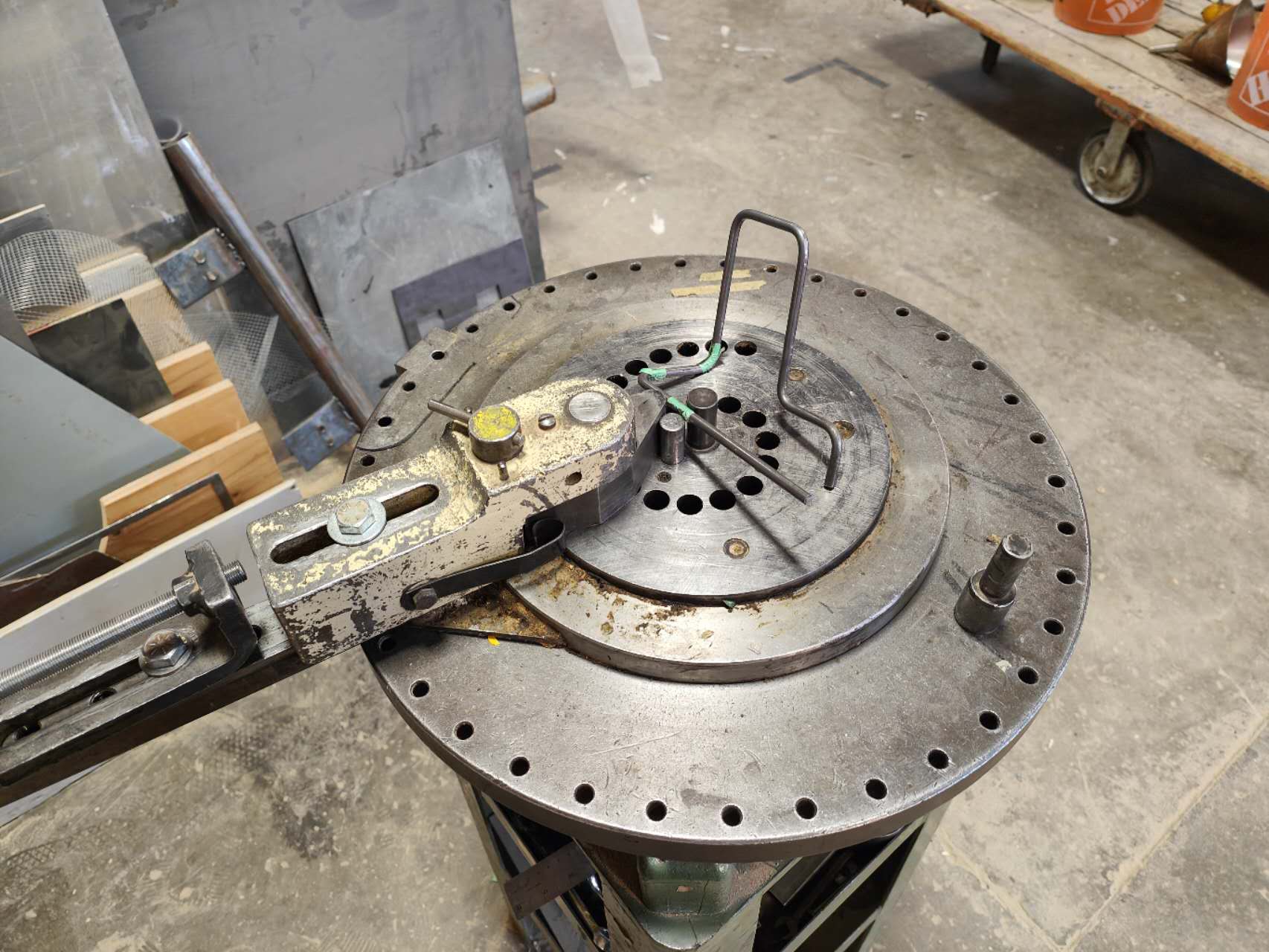

Roll the sheets:

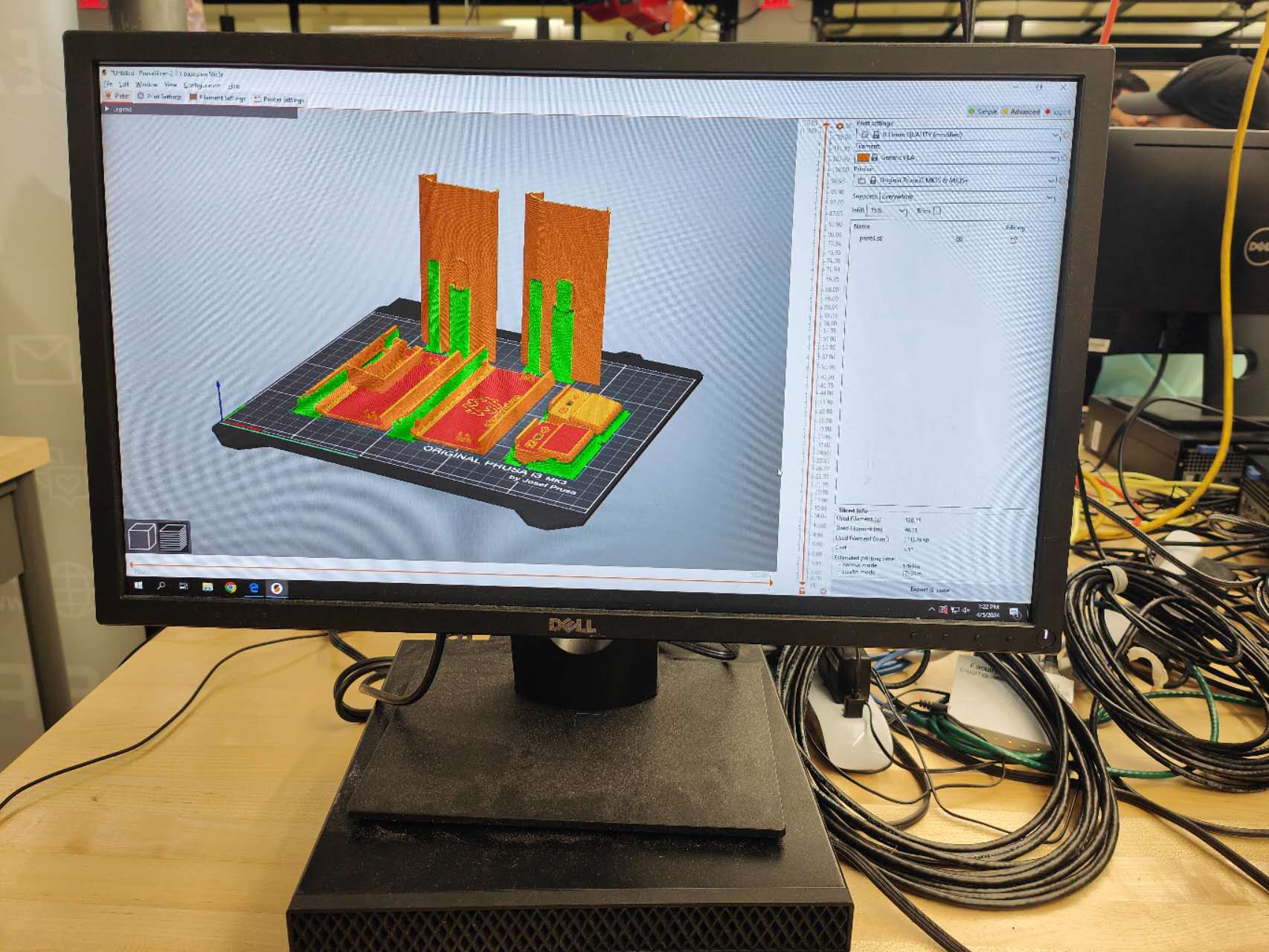

3D printing models help me bending the sheets, because of its special shape, it cannot be bent with sheet rolller, only steel tubes can be bent.

Bend the sheets:

I used different bending methods depending on the size of the part and the Angle of bending.

Welding and Grinding:

The standard version uses spot welding and welding, while the Pro version only uses welding. After welding, angle grinding is performed.

Fill in the gaps & spray paint:

Use bondo to fill gaps, sand and spray paint.

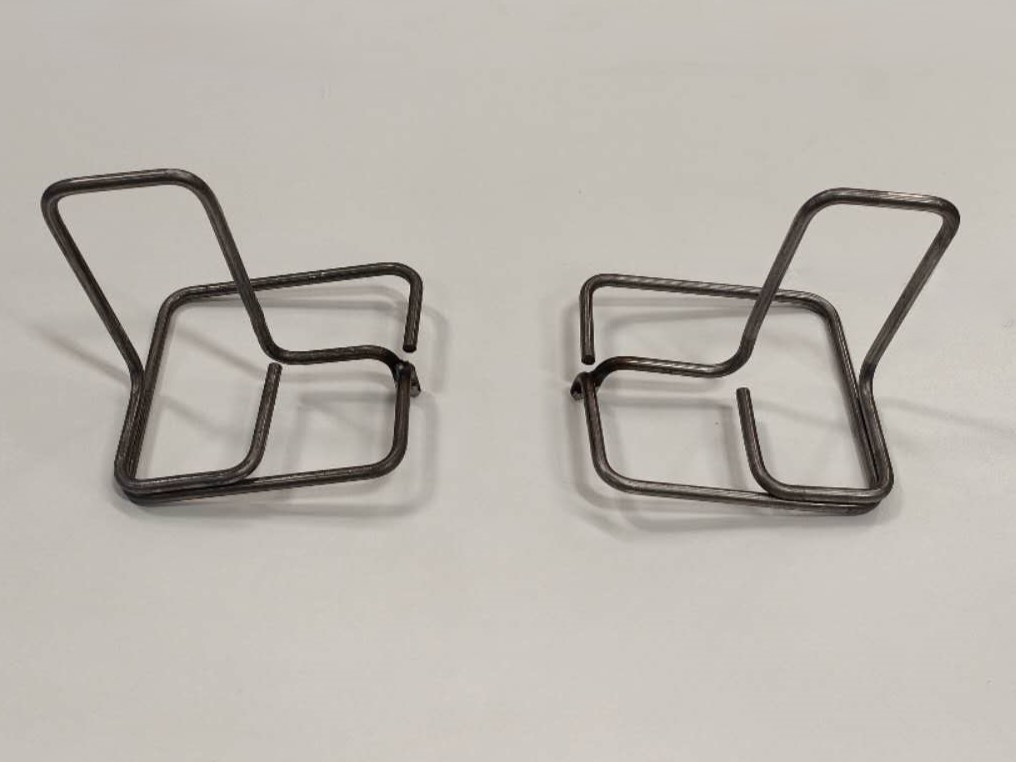

Bending steel robs:

Bending, cutting, welding. more info coming soon…

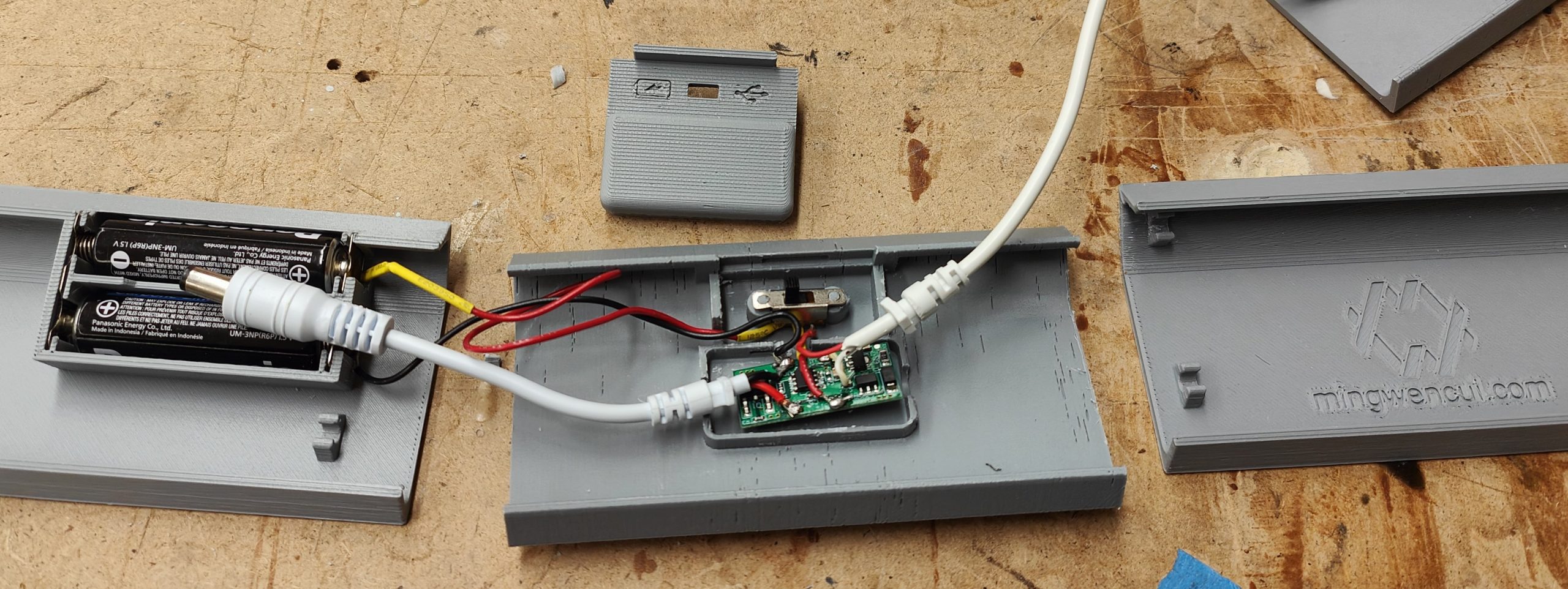

3d printing, soldering iron:

Switch above: used to change the energy source.

Below the mother board: for the front switch.

Price Calculation

Price is for reference only, and material changes may result in inaccurate prices.

Design costs are based on sales volume, and a small number of products cannot reflect formal design costs.

Material Cost (included light & shell):

Labor Fee:

Painting Cost:

Packaging Cost:

Advertising Cost:

Design Fee:

Profit:

$135

$20/h × 7h = $140

$15

$10

5% ($15)

5% ($15)

10% ($30)

Total:

$360

Price account

Price is for reference only, and material changes may result in inaccurate prices. Please refer to the actual price.

Material Cost (included light & shell):

Labor Fee:

Painting Cost:

Packaging Cost:

Advertising Cost:

Design Fee:

Profit:

$135

$20/h × 7h = $140

$15

$10

5% ($15)

5% ($15)

10% ($30)

Total:

$360

Final Prototype Images

The Shelf with bookends

The image and video below is before spray painting.

All photo and Videos taken at UofA Industrial Design Studio, April 12 – 15, 2024